Goods-to-Person vs. Person-to-Goods Automation: A Complete Guide (Part 1)

For many 3PLs and eCommerce retailers, the key to realizing greater productivity across their operations is warehouse automation. At its most basic level, warehouse automation minimizes or even eliminates the amount of time and effort that order-picking associates spend walking the aisles and picking individual SKUs in the warehouse. Walking is a low-value activity that detracts from the number of orders that workers can pick per hour. In fact, studies show that warehouse associates can spend as much as half of their work time walking during order picking.

There are two main order fulfillment automation methods: Goods-to-Person and Person-to-Goods.

Goods-to-Person (GTP) is a warehouse automation solution in which products are brought to a person by fixed or Autonomous Mobile Robots (AMRs). Associates receive the items needed to prepare an order at their pick stations without having to move in any meaningful way from their location. In Goods-to-Person (GTP) automation, warehouse robots bring picked products to a mostly stationary associate, nearly eliminating walking and unproductive time.

Person-to-Goods (PTG) picking involves workers traveling the aisles of a warehouse or retail facility to manually select items for an order and then bringing them to an area for packing. This automation method utilizes robot technology and software to cut down on their walking and increase pick rates.

In this article, we’ll define each of these picking automation options and spell out the key differences between them.

What Is Goods-to-Person (GTP) Automation?

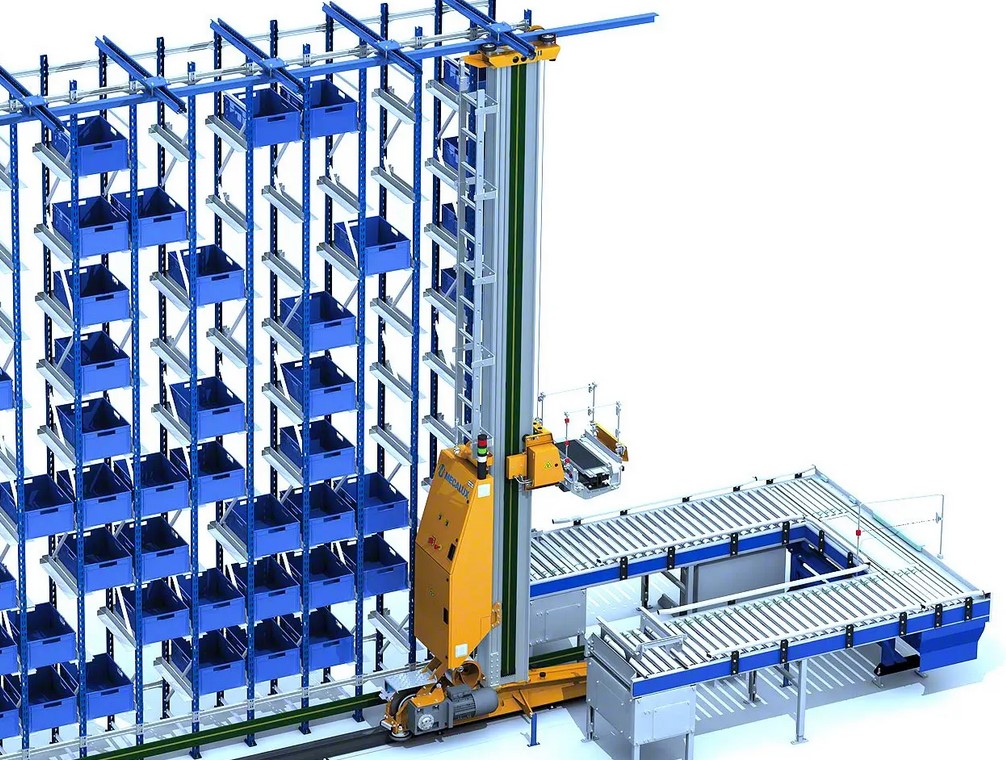

There is a variety of Goods-To-Person technologies. On one end are large, fixed robotic systems like Automated Storage and Retrieval Systems (ASRS), which deliver high productivity rates and provide high storage density. The ASRS pulls and delivers the required items, usually in a tray or tote, to the picker who chooses the items needed. The system then automatically returns the boxes to the rack.

As a large, fixed robotic system, an ASRS delivers high productivity rates, reduces the amount of foot traffic for warehouse workers, and provides high storage density. However, these systems are expensive and require a considerable investment in infrastructure.

On the other end of large robotic systems are mobile automation solutions such as Autonomous Mobile Robots (AMRs). These warehouse automation solutions are more scalable and flexible. AMRs require far less capital investment and generally use or adapt the warehouse’s existing infrastructure.

There are two Mobile Goods-to-Person automation approaches.

Racks-to-Person vs. Totes-to-Person Automation

The “Racks-to-Person” method uses low-profile robots to go underneath an entire shelf of goods, lift up the shelving unit and carry it to an order-picking station. Associates are alerted to the items to pick and appropriate bins to stow items. The disadvantage to a racks-to-person approach is that people and machines often work at different paces. Racks and goods can pile up while an associate takes a break. During peak periods, robots may bring more racks to the order-picking station than the people can handle, and again, the result is a bottleneck.

The “Totes-to-Person” method uses AMRs to bring a specific tote rather than an entire rack. For example, robots remove a tote from a shelf, bring it back to a put-wall, and stow it on a shelf. Later, picker associates pick items from the totes. Travel for the associate is limited to a small area, which saves time and injury risk from prolonged warehouse travel. Some systems decouple human and robotic processes, allowing humans to work in bursts, while robots can operate 24/7.

Part one of this article has offered insights into the G2P automation method. Stay tuned for part two, where we will delve deeper into the P2G automation method and explore the key distinctions between G2P and P2G!

Source: InviaRobotics