Strategies for Effective Inventory Control in the Dairy Industry

Consumers in Vietnam are increasingly recognizing the importance of milk. This growing demand reflects a shift in perception – from seeing milk as an occasional treat to considering it a crucial part of a healthy lifestyle. However, this surge in popularity masks the complex challenges faced by those responsible for bringing milk to consumers. According to recent statistics, the average per capita consumption of milk in Vietnam is 27 liters per year. Behind the efforts to deliver products to consumers or stock shelves in supermarkets lies the story of distributors, retailers, and manufacturers facing numerous challenges in storing and managing this type of inventory.

Depending on the scale and responsiveness of the business operating milk storage/distribution warehouses, managers often need a specific and effective inventory management strategy to optimize inventory costs. The inventory management strategy for dairy products usually focuses on three main goals based on the following characteristics of the product: Tracking inventory, ensuring quality, and meeting market demand.

What are the characteristics of milk products?

Milk products are one of the products with perishable properties and require special storage conditions. This poses major challenges for inventory management for businesses in the dairy production and distribution industry. Not only need to be handled carefully right from the production stage, but at the finished goods storage stage, managers need to track the number of imports/exports, lot number, production date/expiration date, leadtime, storage temperature, shelf life, etc. of each milk lot accurately to avoid spoilage of the lot.

Key considerations for distribution/retail/production milk warehouses

Tracking the amount of inventory is one of the most important points when managing milk inventory. Managers need to ensure that the inventory amount is updated regularly and accurately to avoid stock shortages or surpluses. If you import too little, it will not be enough for business, if you import too much, it will cause congestion, making it easy to lose storage and operating costs.

In parallel, the shelf life and expiration date of most milk products on the market are relatively short, about 3-7 days for pasteurized milk products, 6 months to 1 year for sterilized milk, and 1-2 years for powdered milk if stored in the correct temperature conditions. In reality, the time for the warehouse to receive products is also affected by the lead time for delivery from the distribution center or production plant. Therefore, the task of managers is to ensure that the lot when received must be managed and calculated at the correct time of entry and must be processed for export before the allowable storage time.

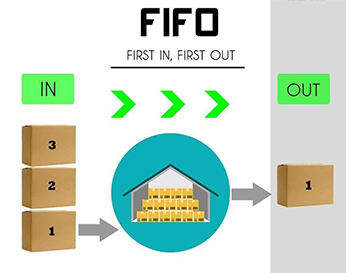

And one of the most commonly used export/import management methods in the dairy industry is the FIFO method – “First In First Out”. According to this method, the goods (lots) that are first entered into the warehouse will be the first goods to be exported from the warehouse. The remaining lots will be the goods that have been imported recently. It sounds simple, but with large distribution or retail warehouses that need to manage a large number of milk, many product codes, applying FIFO manually can be quite cumbersome.

At the import stage, managers and warehouse documentation staff need to have quality control measures for incoming goods. This will ensure the quality of milk lots during storage as well as avoid causing any unforeseen incidents.

Another risk in managing milk inventory is the return or recall of lots. In the event that the lot is recalled by the company due to errors in the production process or the condition of export does not meet quality standards, the inventory management section must quickly receive information and quickly trace all related information.

So what is an effective milk inventory management solution?

One of the solutions that businesses are applying to support milk distribution warehouse management is to deploy the WMS warehouse management support system and switch to barcode management. This is an optimal solution to optimize the ability to manage the overall status of inventory, including quantity, location, expiration date, and other related information, helping warehouse managers of milk or food distribution to operate smoothly and reduce human errors. Specifically, the WMS warehouse management system can support:

- Accurately tracking inventory information and status: Automatically tracking the time of receiving product lots in real time to support product traceability and increase response speed during product recall.

- Automatic control and planning of import/export plans: The system maintains a history of when each lot was received or produced, making it easy to identify the product order and schedule the lot to be exported better according to the FIFO principle.

- Warehouse management by barcode: Storing barcodes for each product item will save more time searching. Management on the WMS system based on barcodes is also easier when digitizing items in the warehouse.

- …

Reducing the risk of managing inventory for milk products with a short shelf life requires a comprehensive approach that includes a variety of storage solutions, tight control procedures, appropriate inventory processing methods, and the application of modern information systems.

Where to find warehouse management system for dairy distribution/production/retail warehouses?

At TSL, we understand the challenges of the dairy production and storage market. TSL’s suite of WMS software solutions and barcode equipment has been supporting 3+ large customers in the Vietnamese dairy industry in optimizing inventory control, providing real-time detailed information. inventory details to support the development of an effective supply chain operations strategy.

Contact us now for free consultation and learn about solutions that suit your operational needs.