RFID Technology in Logistics and Supply Chain

As a company expands its operations, its supply chain naturally grows right along with it. The processes become more complex, which in turn stresses the importance of accuracy at each link in the supply chain. This is where RFID technology comes into play. This technology is especially suited for goods circulation and tracking. For a supply chain, the RFID technology can be used in several aspects, including warehouse management, inventory management, freight transportation, manufacturing, and retailing. With RFID technology, the supply chain can achieve high performance and tracking.

What is RFID technology?

RFID (Radio Frequency Identification) is a term used to describe a system that identifies objects (things and people) by radio waves. Due to the use of radio waves, RFID systems do not emit light as in barcode technology. These radio waves can travel longer distances (up to 10 meters) and penetrate certain types of materials thus making goods easier to identify.

Structure and operating principle

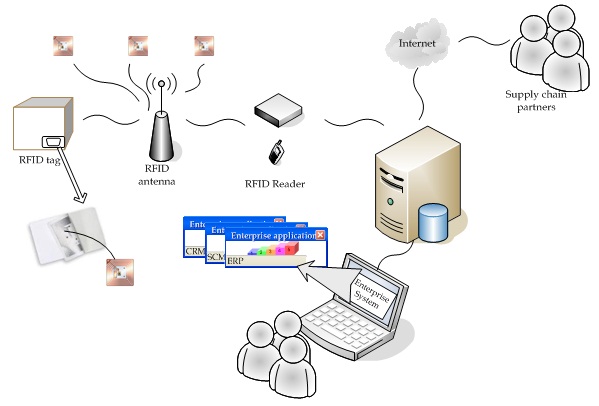

An RFID system consists of three basic components: an RFID tag with a chip (tag), an RFID reader (reader) and a supporting IT system. RFID tags can be classified into two types: active tags and passive tags. Active RFID tags have a built-in power source (such as a battery) and therefore have a higher storage memory and detection range than passive tags. The detection range of active RFID tags is from 20m to 100m while for passive tags it is 2mm to 4.6m. However, due to the dependence on internal energy source, active RFID tags have a limited usage time (number of scans) compared to passive tags. For passive tags, the lifetime is unlimited, because the RFID reader will be responsible for supplying active power to these tags.

When an RFID tag is placed in the identification field of the reader, the data contained in the tag will be recorded by the reader and then transferred to the IT support system through standard interfaces to serve the operations process, analyzing and storage…

The chip attached to the RFID tag holds more data than a conventional barcode, so it can provide more information related to the goods. For example, not only the name of the product, the name of the manufacturer, the country of manufacture, but also the date of manufacture, the date of shipment, the name of the producer…

Unlike barcodes, data stored on RFID can be modified and updated. Due to the very fast data reading time, the RFID filter can recognize many different tags at the same time.

Applications of RFID in Logistics and supply chain

Radio-frequency identification (RFID) technology can provide many benefits that significantly reduce and eliminate redundancies in an extended supply chain.

1. Provide real-time inventory tracking

RFID can simplify and speed up the inbound and outbound processes of the warehouse, providing the exact location of the products in the warehouse to make it easier to find.

Having accurate item stock information combined with up-to-date store stock information helps retailers make timely inbound decisions to avoid a single item out of stock. Efficiency in inventory management can help retail businesses save significantly on storage costs.

It also helps them find the optimal inventory level so there is no excess product sitting on the shelves, wasting money for storage. While adjusting inventory levels may not seem like a profit driver, keeping proper inventory levels can help a company save between 20-30 percent on its warehousing and storage costs.

RFID is able to scan each unique SKU number and identify differences in products, such as size, color, and style. With merchandise tagged with RFID, manufacturers are able to more readily increase inventory count rates from 200 to upwards of 12,000+ items per hour (of course, this is also dependent upon how products are stored and how easy they are to access.

2. RFID Improves Visibility

RFID allows companies to track their supply chain workflow, which will provide more usable data with manufacturing equipment, inventory, asset management, and company processes.

For example, on a truck with a REID tag, when the truck passes through a warehouse door or a checkpoint, the RFID filter will record the exact time the truck entered, exited, departed or arrived, thereby managing its operating status. An RFID-enabled user authentication and access control system can help warehouse managers improve security and enable tracking of a wide range of material handling equipment and other devices and systems.

3. Reduce Loss, Theft, and Shrink

RFID tagging also helps keeping track of any moving products that are not authorized to do so. This is especially important with high-value products like computers, televisions, and automobiles. Sometimes the mere appearance or knowledge that RFID tags are attached can reduce the potential of theft.

Limitations of RFID

RFID also has limitations due to the laws of physics. Metals and liquids have the property of blocking radio waves, so usually RFID does not work effectively in environments with many metal objects or liquids around. RFID tags can also be damaged and become unrecognizable. Interleaving between RFID readers can also prevent an RFID tag from being read. However, advances in technology may provide solutions to these problems in the near future.

Future RFID technology

While in the past RFID technology was limited to certain environments, there are now tags that can be used in harsh environments like extreme temperatures or chemical contaminants. RFID’s flexible applications, increased efficiencies, and cost-effectiveness have made it popular in a variety of industries.

Advancements in printed electronics have helped create new classes of extremely thin, flexible RFID tags that can now be combined with printed sensors, printed batteries, thin-film photovoltaic solar cells, and other technologies. With new electronic printing and conductive ink technologies, companies could conceivably print their own chipless RFID tags on site.

There are also companies working on 3D printing technology that would enable direct printing of electronics in products as they are rendered. While the printing of RFID tags directly inside products may be several years away, the technology is rapidly evolving to do so.

RFID will increasingly be one part of a whole ecosystem of sensors and communication technologies that will help companies better monitor and manage assets and shipments. Passive sensors for temperature, moistures, pressure, vibration and other factors will be combined with RFID to provide even more intelligence form the edge of the enterprise.