Cross Docking – A factor that reduce costs in warehouse operation and supply chain

According to the report of the Emerging Market Logistics Index 2021, Vietnam’s logistics costs account for more than 20% of GDP. Meanwhile, the average logistics cost in the world is only about 11% of GDP. The difference is almost double, but the quality of service is not high. Traditionally, logistics in the supply chain consists of goods transportation to a warehouse, storage, assembling, and dispatching to a retail outlet or end consumer. To reduce costs, this is the time when Cross docking is needed – an important factor in making logistics services profitable and bringing high value, especially in warehouse operations.

What is the Cross Docking and how it works?

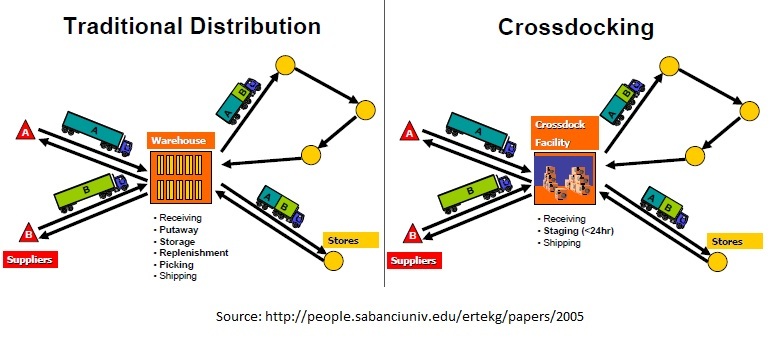

Cross Docking is a logistics technique that eliminates the storage and collection functions of a warehouse, goods will be shipped directly to the manufacturer or supplier to the point of consumption and most of it is not transited through the warehouse.

In the traditional model, warehouses maintain stock until a customer order arrives, after which products are picked, packaged, and shipped. When additional orders arrive at the warehouse, they are stored until the customer is identified.

In the Cross Docking model, the customer is informed about the product arriving at the warehouse and the product has no need for storage. Therefore, the feature of Cross Docking is that the time the goods arrive at the warehouse and the place of discharge are known in advance.

Cross Docking technique requires the rhythm and harmony between receiving – delivery activities. Shipments in Cross Docking typically take about a day and sometimes less than an hour. As a result, it significantly reduces distribution costs in logistics activities as well as increases the efficiency of exploitation or receives goods stored and immediately loaded onto trucks to be transported to the specified destination.

Cross Docking classification

Based on many different criteria, Cross Docking is divided into 5 types, including:

1. Opportunity Cross Docking: Can be used in any warehouse. Move a product directly from the receiving area to the shipping area in response to a known need. For example a customer order.

2. Retail Cross Docking: This process involves receiving products from multiple suppliers. Them, sorting them into the output trucks for a number of retail stores.

3. Transport Cross Docking: This activity combines shipments from several different carriers in the form of LTL. Or in small packages to take advantage of economies of scale.

4. Distributor Cross Docking: Collect input products from different suppliers into a mixed product pallet. This pallet will be delivered to the customer as soon as the final component is received.

For example, computer parts distributors can source components from different suppliers. And combine them into a single shipment for the customer.

5. Cross Docking Production: Support and gather input supplies to support Just-in-time in production.

For example, a manufacturer might rent a warehouse near their factory. And they use it to prepare for assembly or assemble the necessary components of each part. Because the needs of each part are known in advance. Based on the output of an MRP system (manufacturing resource planning system). So there is no need to maintain a certain amount of inventory.

Products suitable for Cross Docking

Using Cross Docking is effective when a product is delivered in small volumes but with a varied assortment. In the Cross Docking terminal, small batches can be consolidated into a large one and sent to one receiver. This method is also used when goods from several suppliers have to be shipped to different receivers. This allows gaining time by processing a large number of orders, which is especially relevant during peak sales season.

Due to its features, cross-docking enables to organize logistic processes as efficiently as possible in dealing with such types of freight:

- Perishable foodstuffs (meat, dairy, vegetables, fruits) that require immediate shipping.

- Orders are assembled and packaged for quick delivery.

- High quality item without quality inspection during receipt.

- Major retail product categories with a steady demand and low volatility or products with a fixed sale date.

Cross Docking’s Role in Warehouse Operations and Supply Chain

Cross-docking simplifies a company’s logistics processes and allows to track efficiency at any link of the supply chain. It also eliminates considerable warehousing costs. A cross-docking warehouse is designed to handle incoming and outgoing goods flows as efficiently as possible, and has a large number of through gates. The receiving of goods is arranged so that freight can be easily transported from the reception area to the expedition area for delivery to consumers. It also eliminates costs for unnecessary services and warehousing. Also, the fact that goods are delivered to an end consumer very fast reduces the risks of their spoilage. Thus, a business suffers fewer losses in goods transportation.

Cross-docking allows faster delivery, which increases customer loyalty. In addition, part of the product value includes transportation and storage. Since goods are not stored in a warehouse for long-term storage, and a business does not pay for this stage. So the value of the final product is also reduced. This makes the product more attractive to consumers and becomes an important competitive advantage.

Cross-docking enables supply chain optimization, delivery terms reduction, and work with large flows of goods with minimal staff involvement. This service is needed by companies that do not have their warehouse. However, it is worth considering that if a business does not have its transport fleet, it cannot organize a cross-docking process on its own. In such a case it makes sense to order this service from a 3PL provider.

*Source: Synthesis