What is WMS solution?

Maintaining unreasonable inventory greatly affects production and business activities. Therefore, effective warehouse management is the solution to reduce costs and increase revenue for businesses.

Many years ago, Vietnamese enterprises struggled to find more scientific and effective options to help them strictly manage the supply chain and avoid errors in this chain. However, all of these manual options are only making slow changes, and businesses are still swimming in the black hole of supply chain problems.

Until TSL bought Blue Yonder warehouse management solution to Vietnam

Warehouse management is a real-time distribution center management solution based on comprehensive SaaS. The solution cleverly addresses supply chain interruptions, creating a competitive advantage for the business.

The solution is applied technology to optimize tasks, ensuring every aspect of the goods’ movement is implemented in the best way.

It is a comprehensive, mobile-ready solution for inventory distribution and management, including labor management, yard management, domestic operations, inventory management, single processing: operations, external activities, third-party logistics operations, and business analytics.

WMS and notable changes

Warehouse management system (WMS) is built from the application of new technology to empower each user. The system provides a specific management mechanism for each role, allowing users to track work and handle issues that arise in real-time, thereby increasing their maximum productivity.

WMS simplifies the operation process in the warehouse, speeding the circulation of goods in the warehouse. The process is user friendly, helping them control their activities better, and be proactive at work. More importantly, the solution has upgraded the entire warehouse system of the business, making it faster, more accurate, and economical.

The WMS warehouse management solution’s core function is to help managers and employees manage inventory through warehouse operations such as a receipt, storage, loading, unloading, loading, and transporting.

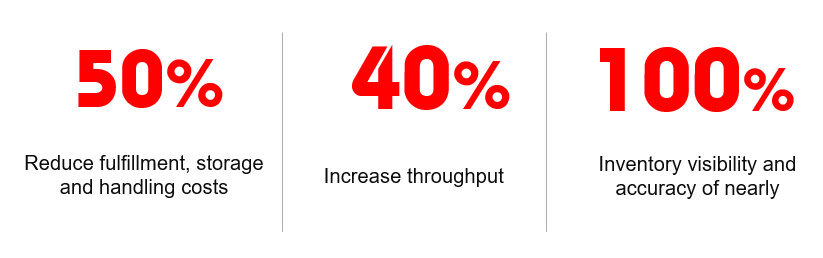

Notable changes that Blue Yonder WMS brought to businesses

What factors made the warehouse management system of Blue Yonder

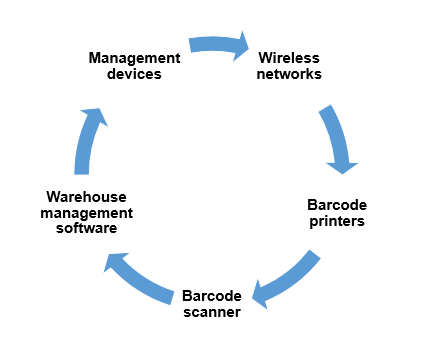

The warehouse management system (WMS) consists of 5 components:

1. Warehouse management software: Warehouse management software includes available functions and standard processes.

2. Management devices: Computers, Laptops, Mobile Phones, and other smart electronic devices. These are tools to help businesses install, apply, and use WMS.

3. Wireless networks: Wireless networks help businesses update the actual situation in the warehouse anytime and anywhere.

4. Barcode printers: Depending on the desires and specific business strategies of the enterprise, each product of each business will have different barcodes. Barcodes on each product, batch of products, are the integrated information about product code, item name, supplier, unit, product origin, and serial number.

5. Barcode scanner: Barcode scanner has the task of connecting with a computer to read barcodes on products, batches of products created earlier when warehousing, ex-warehousing, and even payment.

Add value from working with Microsoft

Blue Yonder has overcome the challenges of traditional IT in management by converging the best solutions. First of all, it is impossible not to mention the cooperation with Microsoft, a notable highlight that contributes to the added value of this solution. It was this collaboration that helped the company build a cloud-based ecosystem to optimize system responsiveness. The application of this technology has helped eliminate the technology cycle burden.

Blue Yonder has partnered with Microsoft to bring solutions to the market on the Azure platform. The Azure ecosystem has proactive monitoring and provides an extended and secure approach through the API Gateway, thereby promoting warehouse operations through the Luminate platform.

And here are the remarkable results from this cooperation:

Functions of the warehouse management system (WMS)

Integrated distributed order management

Integrating easily with other systems in the enterprise creates a comprehensive information ecosystem, providing complete and accurate information for in-store decisions—especially the activities related to the procedure of delivery and delivery of mail.

Synchronized interleaving

Information is updated throughout the system, tasks are performed continuously, alternating, and in order of priority—all towards the common goal of maximizing service efficiency.

Advanced visibility

It allows managers to predict future indicators based on historical activity, resources, and current work situation.

Robust analytics

Warehouse tasking’s analytical tools define the right parameters for maximum efficiency. Thus businesses can predict the number of employees based on demand.

Flexible allocation

Using warehouse tasking allocation capabilities, businesses can allocate items most effectively without spending a lot of time, even in changing conditions.

The warehouse management system helps businesses scientifically arrange warehouses to help find, transport, import, and export goods faster, saving time, and workforce. The arrangement and arrangement of products and scientific materials help to protect warehousing areas, increase labor productivity, and facilitate convenient and convenient ex-warehousing, management, and control. Warehouse management software (WMS) helps users improve the efficiency of inventory control operations.