How is market condition after the COVID-19 period and what is the problem solution?

The international economy is facing the difficult problems caused by the Covid epidemic, especially in sectors such as food & beverage, and vehicles. Many countries have released alarming figures about the economic downturn in 2020 and not decline in 2021. However, objectively judging, the Covid pandemic has also awakened the management awareness of many businesses, especially in logistics. The impact of a pandemic will more or less help them change how to operate to improve the system for the better. The following market-leading experts will highlight Covid’s impact on the economy and Blue Yonder’s contributions in this context.

The effect of COVID‐19 pandemic on global markets

According to Mr. Nicolas Cron, most countries are experiencing an economic slowdown. In Japan, F&B revenue has dropped to 34.4%, while this figure in 2019 is 35.99%. Noticeably, India, when research on this country shows that the automotive industry will show no signs of stabilizing until 2021. Even the metal sector in this market is facing problems.

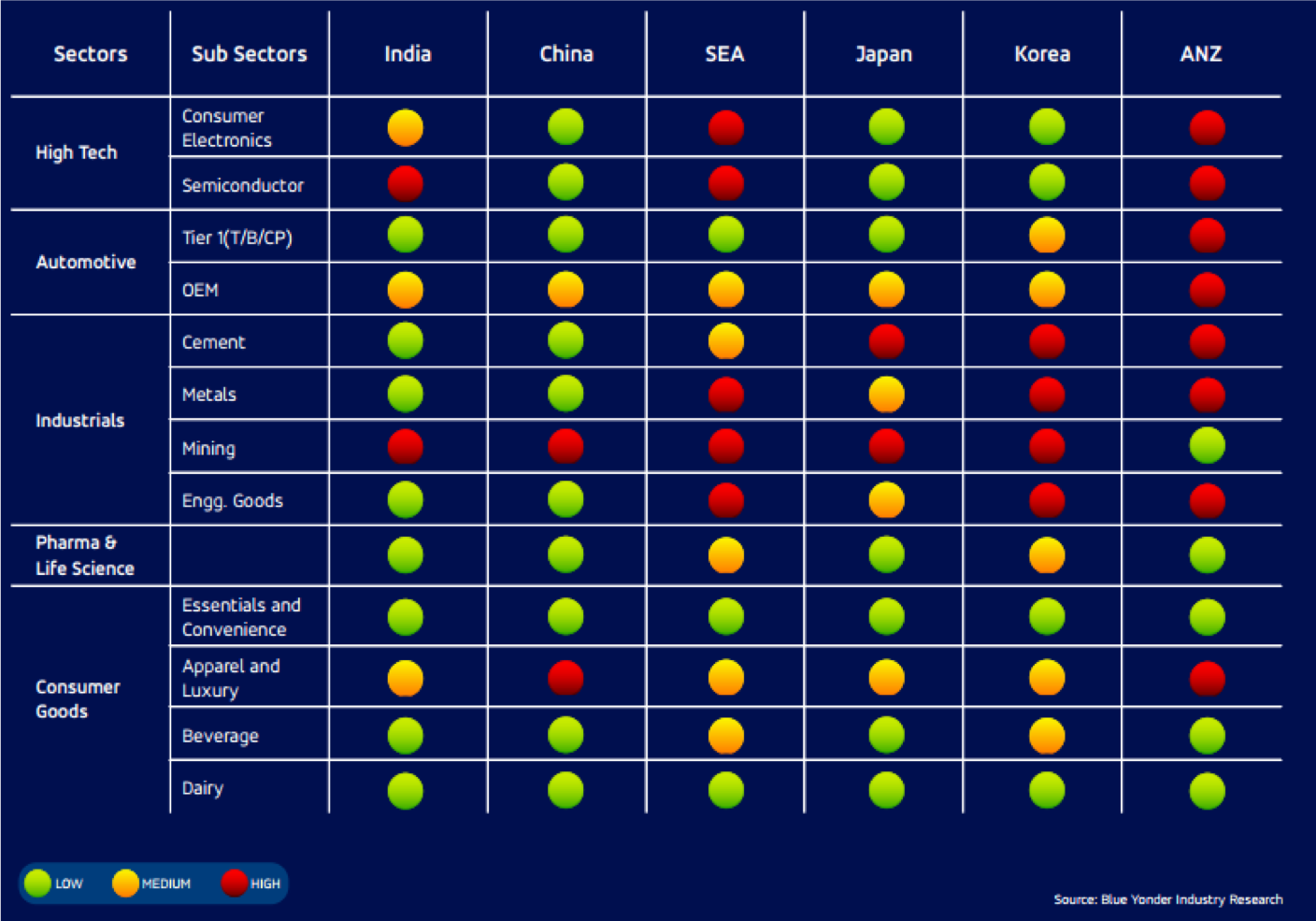

Market Attractiveness Index (Manufacturing) Future Outlook 2021 – 2022

Market Attractiveness Index (Manufacturing) Future Outlook 2021 – 2022

Besides, Mr. Hong Mo Yang, a specialist in the field of Blue Yonder’s production, also gave some views on the production situation. Before joining Blue Yonder, he worked as a commercial director for many large businesses and SVPs at Samsung. Thus, he understands the situation that businesses are facing today.

To achieve “Resilient lean” in the supply chain, the Blue yonder offers some of the following suggestions for the enterprise.

1.Provider network evaluation

It’s no wonder manufacturers in the Food & Beverage industry are facing and managing the challenge of reusing targeted inventory for different channels during the COVID period.

2.Increase search visibility

A prime example of pharmaceutical companies, given the need to streamline supply chains, research and understand which transportation options can get them to the place most quickly and concentrate on it.

3.Taking advantage of the technology’s development

During the times of Covid, powerful AI / ML technologies applied to the supply chain have proven to be efficient and have earned confidence in manufacturers’ responsiveness better than manual options.

4.Increase adoption of e-commerce

Some experts point out that in COVID-19, the adoption of E-commerce has significantly accelerated. The ability to apply digitally to planning delivers visibility becomes even more important to many businesses and gives them a sustainable competitive advantage.

During the COVID-19 period, almost everyone knew about the phrase supply chain, which demonstrates the supply chain facing big difficulties. Manufacturers are tending to reduce the number of SKUs and only provide the core SKU groups to drive customer satisfaction. Thus, the crucial thing that businesses should do is to build a compact and ready-to-respond supply chain system to promptly respond to changes in the business, he shared.

Other perspectives on of the Covid -19 pandemic’s influence

While most businesses only see the negative side of the Covid epidemic, some experts still see its positives.

Mr. Amlan Bose – COO & Senior Vice President of Smart Link Technology Co., Ltd, shared another view of the Covid epidemic, he said:

All businesses are facing a serious impact from the Covid -19 epidemic back after 100 years. But, positively, Covid has the effect of driving the global transformation where people are at the center.

1. Changing customer needs and delivery method

Global industries are facing a completely new challenge, customers are constantly changing demand from marketing channels to responsive methods. This forces companies to re-visualize their business models and approach to quickly implement the right mode of delivery. The world is used to the promise of 24-48-72 hours delivery through retail malls. But overnight, expectations have changed to an online order that can deliver 30 minutes. This is imperative for organizations to re-establish and move towards a Whole New Mindset, a whole new set of business processes & behaviors that aligns with future development trends, and clearly, it has been fueled by the Covid-19 pandemics.

2. Essential trends in demand forecasting

The appearance of Covid -19 has made businesses more aware of the role of demand forecasting, a key factor affecting the efficiency of each enterprise. When we need to have the right and enough supplies, and limit inventory, it is more important to forecast customer demand. Of course, this ability needs to be supported through machine learning (ML), artificial intelligence (Ai). Simply put, businesses need the support of digitalization to do this.

3. Promote steps towards Industry 4.0 ecosystems

Industry 4.0’s hyper-connected world will help machines connect and form an overview and seamless information ecosystem. This connection provides managers real-time information to promptly control developments in the supply chain and make the most effective and optimal management plans.

4. Creating a people-centered organization

It may be that the evolution of smart machines and devices is making us forget the important role of people, but the Covid-19 boom makes us realize the importance of people in the supply chain. And from that, we understand more clearly that – the ingenuity, health, and safety of people is the decisive factor for the long-term sustainability of people. When we see the right role of humans, the more important it becomes that the technology we need to design support becomes more important.

The role of the Blue Yonder & TSL in the Covid-19 Pandemic’s context

Blue Yonder’s solutions are making a big contribution to helping businesses solve the problems of Covid-19 translation as well as taking advantage of the opportunities it offers by analyzing the impact in multiple directions and making effective plans.

– Predictive demand planning with real-time demand sensing

– Integrated planning & execution to deliver

– Synchronized & responsive planning

– Predict disruption and pivot at speed

– Fulfillment precision: Tighten on Time in Full (OTIF) windows

– Pervasive intelligence: ML-powered digital assistance with the built-in intelligence

As a partner of Blue Yonder in the Vietnamese market, TSL is helping many businesses transform their supply chains. We enable companies to achieve sales improvements, improve customer satisfaction, and save costs.

Source: Blue Yonder Inc